Biolab Parafuel Nir In-line Analyzer

Biolab

Product Code: Parafuel

Brand: Biolab

GET OFFER: info@imtek.com.tr

Description for Biolab Parafuel Nir In-line Analyzer

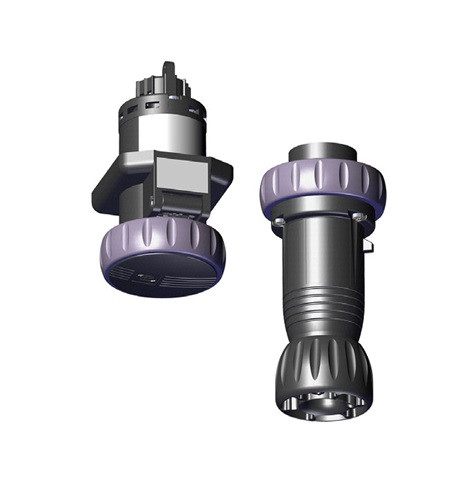

The ParaFuel™ NIR Process analyzer from LT Industries provides comprehensive inline analysis of Diesel, Gasoline, Jet Fuel, Kerosene, Crude Oil, Blending components and Blended Fuels for a wide range of critical properties including Octane, Distillation Points or RVP. The analyzer is also available in a benchtop version designed to improve efficiency when testing in laboratories.Validate Fuel and Crude Oil QualityWith the ParaFuel™ analyzer, accurate measurement of the properties of petrochemical products and crude oils is easy. Whatever the analytical need – inspection of crude oil or finished products, inline property measurements, or validating shipments – the ParaFuel™ can do the job. The optical analysis technique allows for easy integration and rapid inline measurement. ParaFuel™ Process Systems measures key chemical and physical properties rapidly and accurately directly in process, to monitor changing process conditions in real time and to adjust as necessary. The simple test procedure allows for greater experimental repeatability — and it does not require special operator skills. Inline Testing of up to 20 measuring points With the capability to measure 20 points with a single analyzer, you can validate quality and performance at all stages — from crude samples at the well to downstream refining. Improve your process knowledge and control.Measure in process or in the laboratoryThe ParaFuel™ Process Analyzer comes complete with probes and flow cells built to suit your measurement needs. They are available in a variety of lengths, configurations and materials depending on your measurement requirements. High pressure and temperature sampling probes can withstand the conditions associated with oil production and refining. Instruments are designed for direct integration into existing control systems via the LTBus automation & communication software. The ParaFuel™ Analyzer can communicate directly via standard protocols such as Modbus and 4-20mA. The ParaFuel™ Benchtop System provides the same high quality measurements as the process system.Key FeaturesDesigned for 24/7 operationMeasure up to 20 process points with one analyzerProbes and flow cells for continuous processesEasy integration into existing DCSFully automated user interfaceRemote diagnostic capabilityRemote update capabilityEnclosures for protection against dust, water and environmentReal-time-AnalysisAutomated, nondestructive inline analysis, completed within seconds. Results sent to your DCS, PLC, or LIMS.Control the use of high-value crudes and chemicals — Measure concentrations and use only what you needValidate quality throughout the process — Determine where and when product falls out of specificationMake process adjustments in real time — Reduce waste by adjusting processes rather than discarding batchesReduce energy consumption and increase process efficiency — Accurately determine concentrations and reaction progressDesign quality into your process — Achieve higher standards than are possible with batch testing aloneBenefitsParaFuel™ analyzers are utilizing LT Industries´ knowledge of over 30 years experience in developing NIR analyzersFast inline or laboratory measurementReal time monitoring of multiple process streamsAutomated results on a simple interfaceValidation of incoming productImproved product qualityImproved repeatabilityReduced expensesMinimal operator trainingRapid return on investmentModels Available: ParaFuel™ NIR Process Analyzer Single System Includes one (1) High Energy Bubble Shedding ProbeParaFuel™ NIR Process Analyzer Multi-System Includes Multiplexer and Up to twenty (20) ProbesParaFuel™ NIR Benchtop Analyzer Includes one (1) Dip ProbeFuel Properties (Gas, Diesel, Jet)Common MeasurementsRONVapor PressureMONPour PointCetaneViscosityRVP (kPa)CCRDensity / APIMethanolFlash PointOlefinsCloud PointHydrogenCFPPWax ContentSmoke PointAniline PointSpecific GravityFreeze PointAromatics, v%Cloud PointOlefins, v%Distillation PointsMTBE, v%n-ParaffinsSaturates, v%C/H RatioBenzene, v%Water ContentEthanolYieldsDistillationSARAEvaporationTotal AromaticsColorAPI Gravity / DensityPump QualityEmulsion StabilityAcidity / TANPetrochemical PropertiesSolidsp/o/m-XylenesAsphaltParaffinsTBPIsoparaffinsAsphaltene ContentNapthenesAsphaltene DepositionOxygenatesAsphaltene PrecipitationAromaticsSulfurOlefinsc-NumberAcids in AlkylationBTXHigh/Low RONTechnical Data ALL AnalyzersPower Supply100-240 VAC, 50/60 HzScan time30 seconds (user adjustable)Computer InterfaceStandard Windows PC with LT Software PackageA-C CommunicationStandard TCP/IP EthernetTechnical Data PROCESS AnalyzerClassificationC1D2 Standard, C1D1 OptionalControl System CommunicationModus RTU Standard (Option: Modbus TCP, 4-20 mA)Number of measurement pointsUp to 20SampleUp to 150 C and up to 7000 kPa (1000 psi)Fiber Optic Cable Length3 m standard, up to 200 mSample Temperature MeasurementAutomatic, built-in measurementTechnical Data BENCHTOP AnalyzerDimensions12? x 15? x 13? (30.5 cm x 39.7 cm x 34.9 cm)Data StorageData automatically logged and stored Standard TCP/IP connection for integration into Lab Network and existing LIMSRecommended Products For Biolab