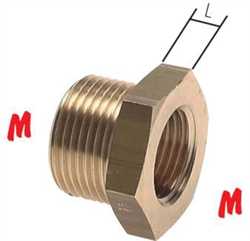

Landefeld Straight screwed-on screw connections with female thread, metric

Landefeld

Product Code: Straight screwed-on screw connections with female thread, metric

Brand: Landefeld

GET OFFER: info@imtek.com.tr

Description for Landefeld Straight screwed-on screw connections with female thread, metric

Description Materials: Bodies: Zinc plated steel, any existing elastomer seal: NBR Temperature range: -40°C to max. +120°C (with an elastomer seal: -35°C to max. +100°C) Montage cutting ring screw connections and NC compression ring fittings 1) Cut the tube away at a right angle and lightly deburr and clean the inside and outside. Do not use a tube cutter. In the case of thin-walled or soft pipes a reinforcing ring must be used. 2) Thoroughly oil the socket threads and cone, inner union nuts and cutting ring. For stainless steel cutting ring connections PASTE ES must be used (optional for NC screw connections). 3) Push the union nut and cutting ring onto the tube. Ensure the correct position of the cutting ring/NC compression ring - otherwise the assembly will be incorrect. 4) Loosen the union nut as far as possible by hand. Attach the marking of the union nut for checking the specified rotations. Press tube in the cone until the stop. Tighten the union nut with screw wrench approx. 1 rotation. The tube must not be rotated. 5) Loosen the union nut to check the assembly. Cutting ring: The raised tube material must cover the front cutting ring area. If not, retighten slightly. Due to the spring effect of the cutting ring, this can still be rotated - no functional error. NC compression ring: The compression ring can no longer be displaced. 6) Final assembly: Assemble the union nuts on sockets until there is a noticeable increase in force. Then tighten with 1/4 - 1/2 rotation (cutting ring fitting), or 3/4 rotation (NC compression ring fitting). Required tube quality: The screw connections must be processed with heat treated, seamless stainless steel tubes (1.4571) according to DIN EN ISO 1127. The tolerance category should be D4/T3, the surface must not show any damage and its hardness should not be more than Rockwel HRB 90. Vorteile NC-Klemmringverschraubungen gegenüber Schneidringverschraubungen: • Compatible with all cutting ring fittings according to DIN EN ISO 8434-1 (DIN 2353). Also resistant to dynamic loads such as vibrations and pulsations. It can be loosened and screwed back in as often as is necessary. • In contrast to a cutting ring the NC compression ring is not hardened, therefore it cannot rust and has good chemical resistance. • Lubrication of the nut thread for initial assembly is not necessary, •Vacuum tightness Q< 10^8 mbar l/s, •Ideal for use in gas and water area GAI 6 LM GAI 8 LM GAI 10 LM GAI 12 LM GAI 15 LM GAI 18 LM GAI 22 LM GAI 28 LM GAI 35 LM GAI 42 LM GAI 6 SM GAI 8 SM GAI 10 SM GAI 12 SM GAI 14 SM GAI 16 SM GAI 20 SM GAI 25 SM GAI 30 SM GAI 38 SMRecommended Products For Landefeld

Eurotherm 3504\Cc/Vl/1/Xx/10/1/Xxx/G/Rr/R4/Tk/Xx/Xx/Xx/Et/F2 Thristor Eurotherm 3504\Cc/Vl/1/Xx/10/1/Xxx/G/Rr/R4/Tk/Xx/Xx/Xx/Et/F2 Thristor