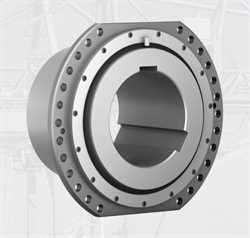

Ringfeder TNK TKV Barrel Coupling

Ringfeder

Product Code: TNK TKV

Brand: Ringfeder

GET OFFER: info@imtek.com.tr

Description for Ringfeder TNK TKV Barrel Coupling

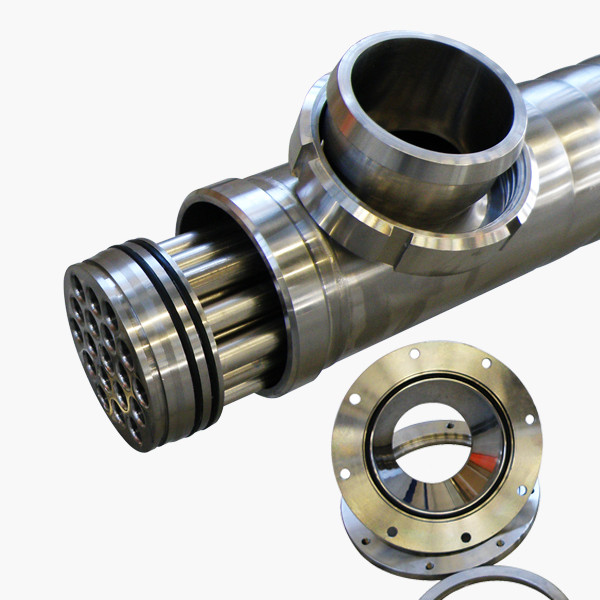

The RINGFEDER® barrel coupling consists of a sleeve, made of reinforced-material, equipped with semi-circular internal teeth and a hub, made of reinforced-material, with semi-circular external teeth of the same shape. In the resulting circular recording hardened steel barrel rollers are used, which serve as power transmission elements. Lock rings on both sides of the barrel rollers serve for their axial guidance. Inner and outer covers, each of which is equipped with a lip seal, effectively prevent foreign matter from entering and lubricant from escaping.The proven design with hub and housing made of high-strength material allows more torque and higher radial force in the same spaceCharacteristics RINGFEDER® TNK serie TKV Barrel couplings made of reinforced-material for use in crane/ hoist applications to support the rope drum. Characteristics Torsionally rigid, compensate for angular and axial shaft misalignment Torque transmission by hardened, barrel shaped steel rollers Equipped with wear indication Outer diameters up to 850 mm Bores up to 425 mm Torques up to TKmax = 815,000 Nm Maximal radial load Frad = 490,000 N FEATURES AND APPLICATIONS The barrel coupling consists of a sleeve, made of reinforced-material, equipped with semi-circular internal teeth and a hub, made of reinforced-material, with semi-circular external teeth of the same shape. In the resulting circular recording hardened steel barrel rollers are used, which serve as power transmission elements. Lock rings on both sides of the barrel rollers serve for their axial guidance. Inner and outer covers, each of which is equipped with a lip seal, effectively prevent foreign matter from entering and lubricant from escaping. Due to the curved shape of the barrel rollers, it is possible to swing the hub relative to the housing, as a result of which angular alignment errors can be compensated. Depending on the size of the coupling, axial displacements of 3 mm to 8 mm can be accommodated during operation. The torque is transmitted by means of two carrier face on the housing and their counter-carrier face into the drum. The screws, used to connect the drum, support torque transmission. By using high-strength materials for hub and sleeve, the transmission capability compared to the type TK could be significantly increased. Barrel couplings are used in material handling technology and especially in crane hoists to connect rope drums to the gear output shaft with minimum axial space. In this application, the barrel coupling transmits high torques and large radial forces and yet acts as a joint. Thus, in a rigid connection of the gear shaft with a lifting drum a three-point bearing (Figure No. 1) and thus a statically indeterminate case would result.Then a high alignment quality is required. However, unavoidable assembly inaccuracies, deflection of the foundation under load, and wear on the bearing cause enormous additional forces has to be absorbed by the stored gear shaft. Alternating bending stress can cause fatigue failure and bearing and gear damage. In order to avoid this risk, barrel couplings between the gearbox and the rope drum are positioned, which, due to their characteristics, compensate angular misalignments. With the barrel coupling in a three-point bearings, a statically indeterminate becomes a statically determined drive train, whereby high bending moments and constraining forces are avoided. Figure 3 shows the assembly of a barrel coupling in a hoist. Taking into account that the coupling absorbs displacements and thus acts as a floating bearing, a spherical roller bearing is to be provided as a fixed bearing at the other end of the drum shaft.Barrel CouplingIn the recommended mounting Fig. 2, the barrel coupling, which is installed between the gearbox and rope drum, performs the function of an articulated joint, thus making the connection statically determinate and avoiding the occurrence of high bending moments.Recommended Products For Ringfeder